By Steve Lasher/photos by Russell Weis

By Steve Lasher/photos by Russell Weis

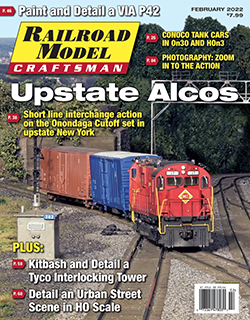

Back in the January 2020 issue of Railroad Model Craftsman, I described how I helped my friend Russ Weis kitbash and detail a Design Preservation Models kit to represent the style of brick towers used along the New York Central (“Freelanced Tower for East Buffalo”). His freelanced HO scale layout represents operations in and around Buffalo, N.Y., in the 1950s, and while it does not represent any one place, a considerable effort has been made to follow NYC practices and standards along the way. Another consideration when building models is time management. Neither of us (Russ or I) is getting any younger, so some concessions to expediency are necessary.

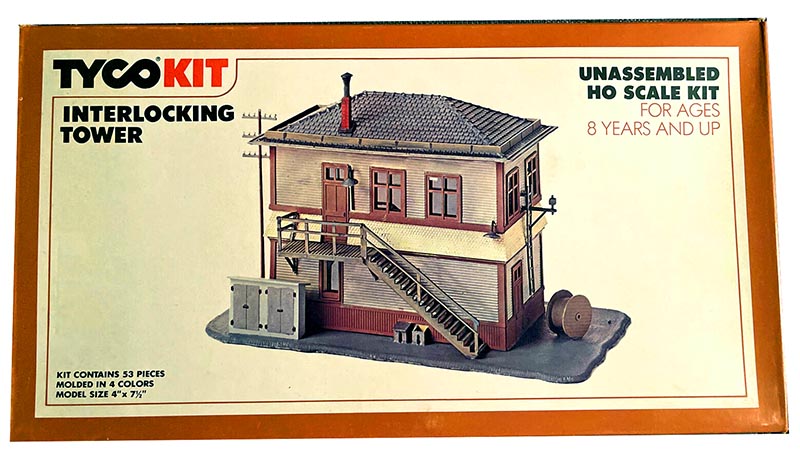

Some time ago I made some rough drawings of a brick interlocking tower for Syracuse that Russ was going to scratchbuild. But, as is the nature of these things, this particular project kept getting shoved to the back burner. It was on an expedition to one of our local train stores (Roundhouse Electric Trains in Louisville, Ky.) when I found the Tyco Interlocking Tower kit (no. 7773) still in its original dog-eared box. I was tempted to just put it back on the shelf thinking it was “junk” when something told me to take a closer look. The more I looked, the more I could see the makings of a “different” building for the layout. What’s more, New York Central used wooden towers of a similar design.

I confess I enjoy taking what some would consider hopelessly outdated items and reworking them into star players. When someone admires this detailed tower model on the layout and asks who made the kit, I take a certain amount of pleasure in their reaction when I confirm it is indeed “Tyco.” The same kit was later offered by AHM in their “Masterpiece Series” (no. 15602). Both versions are easy to find on the secondary market.

After some gentle persuasion (“Russ, at least we will have something there for a tower until you get around to scratchbuilding one!”), the kit was purchased for substantially less than any modern offering would have cost.

From Sow’s Ear to Silk Purse

This transformation was all possible because of Russ’s fine cutting and fitting abilities, though modelers of any skill level should find this to be a very approachable project. We wanted to cherry-pick the best parts and get rid of the objectionable ones. To us, that meant that the molded-in asphalt shingled siding on the upper floor and the rather crudely cast terra cotta tile roof had to go.

The first order of business was to get rid of the shingling on the second floor. I was initially concerned about the age of the styrene and the belief that Tyco may not have used the highest quality material to start with. I was afraid that the plastic might be too brittle to be workable. We did have some trouble with smaller parts, but nothing that we couldn’t overcome…