By Tyler Whitcomb/photos by the author

By Tyler Whitcomb/photos by the author

Have you ever considered adding a railroad barge or carfloat to your layout? Not only does it add additional staging room, but it also adds another interesting activity for your train crews. Just about any place where railroads met the water’s edge was an opportunity to move freight cars by barge. Using barges to transfer cars was often much cheaper than building a bridge, and interchange could be set up anywhere a small switching yard or warehouse could be established on the waterfront. Terminal operations like these could also extend a railroad’s territory into a market they might not ordinarily reach on their own rails.

On the East Coast, railroads like the Baltimore & Ohio, Erie, Jersey Central, Lackawanna, Lehigh Valley, New Haven, New York Central and Pennsylvania all had car float operations that interchanged freight across New York Harbor. Barges were also used by Chesapeake & Ohio and Norfolk & Western to transfer freight cars from Virginia to the Delmarva peninsula. On the West Coast, Santa Fe, Western Pacific, and Northwestern Pacific operated car floats across San Francisco Bay; while up in Seattle, The Milwaukee Road used a car float to access its isolated operation on the Olympic Peninsula. Car floats were also used to span the Mississippi River by Illinois Central and Missouri Pacific. A number of car ferry routes also crossed the Great Lakes. Several operations in Canada were used to bridge remote isolated branch lines.

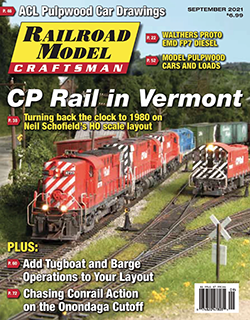

ABOVE: A pair of tugboats from Bunce Towing work hard maneuvering a loaded Tenino Western Railroad car float into the slip at West Bay. Even though they both work for the same company there are many things that set them apart, just like brothers! Maritime operations added a whole new dimension of operations and modeling to my N scale Tenino Western Railroad.

Only a handful of carfloat operations remain active, including a route between Greenville, N.J., across New York Harbor to Brooklyn, N.Y., operated by NYNJ Rail and the isolated Alaska Railroad, which receives its interchange via barge connection switched by Union Pacific in Seattle.

As I delved deeper into the connection between railroads and maritime operations it quickly became apparent my N scale Tenino Western Railroad set in Washington State needed barge operations. This not only opened up a new subject for modeling but also better represented the area I was trying to model.

The Barges

To begin my adventure at sea, I built three two-track barges (or “car floats”), which can be cycled on and off the layout as needed.

ABOVE: A simple build shot of what goes into one of the old Lindberg tugboat kits. Details include brass railings, bitts, horn, searchlight, cowls, and some scratchbuilt parts.

Building the barges was fairly straightforward. Even though I am working in N, these methods can be adapted to any scale. I started by cutting multiple pieces of ½” plywood cut to the size of 3 3/8” wide by 17 7/8” long. Be sure to cut some extras as the wood may warp and you want perfectly flat pieces.

I began wrapping the exterior with Evergreen Scale Models styrene by first adding .040x.375. strips on the lower ends and then adding .080x.250. strips above those before sanding these flush with the sides. I then added .040x.438. strips along the bottom edge on the sides. Be sure to use the 24” strips for everything and not the shorter 14”!

Next I sanded everything to shape. There should still be room for a .060x.060 strip along the top of the sides. For the side ribs I added .015x.060.

Moving back to the topside, I added some Peco Code 55 flex track cut to length. The distance from the sides and all tracks should be a scale 11’ which was filled with .040” styrene. For the spacing between the rails I used .040x.312” pieces. The most important thing here is to be sure all your barges have identical track spacing that matches your apron! Check often during construction so you do not have to try and readjust things since most glues are unforgiving (I had to build five barges to get three good ones). Another tip is to file the end rails at an angle on both the apron and the barges to compensate for any misalignment.

ABOVE: The four tugboats that frequently work the waters along my TWRR are captured in one photo. As I built each tug I learned something new. The Joanna P. is a tow tug, while the Todd B. and Terry B. are harbor tugs, and Russell is a railroad tug. I am having so much fun researching and building tugboats that the fleet is growing very fast! I just wish I had more room for maritime operations on the current layout. Don’t we all wish we had more space?

I found it very helpful to add an end wall, which prevents cars from accidentally running off the ends. I also installed couplers to help prevent runaways while handling the barges, which have been a lifesaver on more than one occasion! The last thing you want to see is a barge full of cars hitting the floor. You could also extend the sides up a little to prevent the cars from going overboard. Work from prototype photos and choose what works best for you.

Barges come in all shapes and sizes and there is usually a prototype for everything. For all the details and bumpers on the barge I used parts from the Seaport Model Works no. SA11 car float fittings kits.

If you do not want to scratch-build your own barges Sylvan Scale Models makes a nice-looking car float kit in N scale (no. N-2066), while Walthers (no. 933-3152 ) and Frenchman River Model Works (169’ 3 Track Car Float) offer kits in HO scale…