Review by George Riley/Photos by the author

Review by George Riley/Photos by the author

While no longer common on today’s railroads, the transport of livestock was among the earliest operations requiring specialized rolling stock designed for the safe carriage of animals. From the mid-1860s to the early-1960s, whole trains of stock cars traveling at passenger train speeds carried vast herds of cattle from collection points in the West and Midwest to feed lots and packing plants located in America’s cities.

By the turn of the 20th century wood-frame and truss-rod cars began to give way to modern rolling stock that featured steel underframes, knuckle couplers, and air brakes. Examples of this type of construction include S-40 class cars built for Union Pacific (UP) and Southern Pacific. Beginning in 1905 and ending in 1918, more than 5,400 of this type of stock car saw construction by six different rolling stock manufacturers in three sub-classes. Early version would begin to be upgraded beginning in 1911 with the adoption of the Safety Appliance Act. By the mid-1920s, Union Pacific would begin a rebuilding program that would repair and cosmetically update many of its stock cars. At this time, the archbar trucks that the cars initially had at the time of their delivery were replaced with Andrews trucks to meet the railroad interchange requirements. The rebuilt S-40 class stock cars went back into service and continued operating into the 1940s before retirement began. The S-40 cars began to leave the roster in the 1940s with the last example being retired in 1951.

Westerfield Models is a seminal manufacturer of precision resin kits. The company has been at the cutting edge of offering accurate historical models of unique and unusual HO-scale rolling stock kits. Westerfield offers kits for at least eight different versions of the S-40-1 class of stock cars. The base kits are less trucks and couplers and sell for $40.00. Westerfield does provide options when ordering to have Tahoe Model Works’ TMW-103 or TMW-203 American Car & Foundry (ACF) archbar trucks included for a $5 up charge. Alternately the builder can use Kadee’s archbar trucks (#501) or Kadee Andrews trucks (#509). The review model is Westerfield’s UP/Los Angeles & Salt Lake S-40-1 single deck stock car (#12551), reproducing Pressed Steel single deck cars as rebuilt in the 1920s. This version and equipped with Tahoe TMW-103 ACF archbar trucks.

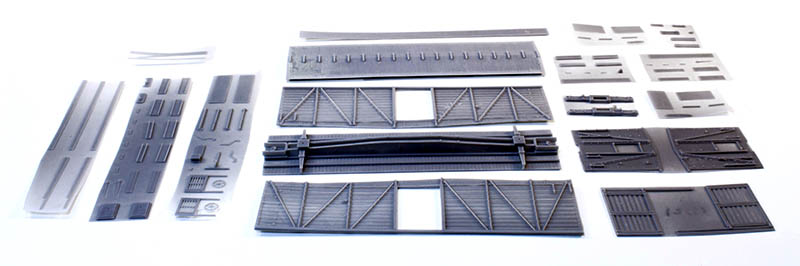

Westerfield kits, by virtue of using molded urethane resin for most of their components, require a bit more experience and patience to complete successfully. Much of the assembly time consists of removing the flash and carrier from these parts. For this a very sharp modeling knife or scalpel, a set of needle files, and several grits of sand paper are required. Despite the flash, which is usual on resin kits, each of the pieces is cleanly molded, fully detailed, and free from air bubbles. You’ll need to clean each of the urethane parts to remove any residual mold release. Greased Lightning household de-greaser was applied to each of the parts and a toothbrush used to get into the crevices. The parts were then rinsed in clear water and allowed to air dry. This cleaning procedure is required, so that both glues and paint will stick to the castings. In addition, when building resin models ACC and epoxy glues are almost mandatory for construction. Both thin Pacer Zap and thick Loctite ACC gel were used to construct this model with the gel used to tack parts together and the thin ACC to flow into the seams of the major parts. This strategy yielded a very resilient model that was assembled quickly without any tell tale glue smears or fingerprints.

Westerfield’s S-40-1 HO kit represents a flat-stock kit in that the body is made up of the individual sides rather than being cast in one piece shell. In a departure from the construction of most craftsman type models, the kit instructions recommend beginning by drilling and installing the wire grab irons prior to assembling the four sides of the car body to the under frame. This proved to be wise council, since the delicate ends and sides were much easier to handle separately than they would have been on an assembled body. The under frame was also assembled as a sub-assembly with the wire airline, injection molded brake casting and brake rigging. Silicon sealer was used to attach the metal weight to the floor. The bolster and coupler pocket was drilled and tapped to accept a 2-56 machine screw. This was not included in the kit and was provided by the builder.

A note regarding the kit instructions, they are complete for every one of the different versions in each of the sub-classes. This can lead to confusion if one is not careful. One work around is to highlight those instructions that are germane to the version being assembled. The only other criticism of the directions is that of the lettering photos are somewhat muddy, making it difficult to determine the type and location for lettering placement. Either sharper images or a drawing would greatly help.

As assembly continued, the component parts fit properly with a minimum of filing and sanding allowing the body to be easily completed. The roof casting was fitted but not glued in place to allow it to be removed so that the interior could be painted when assembly of the model was complete.

A number of additional details completed the model. These included Evergreen styrene strip stock, photo etched stirrup steps and cut levers, pre-formed wire rings, fine phosphor bronze wire, and Tichy Train Group injected-molded styrene parts in addition to resin details included on carrier sheets. The end result was a very detailed miniature replica.

Painting and decaling was the last step in assembling the model. Red spray primer that closely matched the synthetic red paint used by the railroad. A gloss coat was then applied to provide a surface for the kits included decals. Westerfield Models supplies two small sheets of decals; one for each side of the model. They are opaque with even the smallest two-inch scale lettering being legible. The lettering was individually cut from the decal sheets and MicroScale Microset wetting agent was used to aid in the placement of each item. This was followed by applying a few drops of MicroScale Microsol to allow the decals to conform to the surface of the model with out any haziness from trapped air under the film. When completely dry a gloss coat of was applied followed by a dull coat to provide a matte finish to the car.

Tahoe Model Works’ ACF 103 trucks and the recommended Kadee No. 158 scale-whisker couplers finished off the stock car. The complete model meets NMRA recommended practice with a weight of three and a half ounces. The end result is a detailed, properly weighted and free rolling HO-scale model of a widely used, early 20th Century railroad stock car. It took roughly 10 hours to complete the model with a significant amount of this time used to remove the flash from and clean the urethane castings. Anyone with moderate modeling skills and a bit of patience should be able to successfully assemble this model with just a few common hand tools, adhesives and model supplies.

Westerfield Models

P.O. Box 455

Gardnerville, NV 89410

303-658-9343