Trainworx is a name that is well known to model railroaders working in N scale. Over the past 20 years, Trainworx has provided a series of excellent rolling stock and highway vehicle offerings in 1:160. In June 2016, Trainworx began shipping its first product for HO scale — a ready-to-run 40-foot Drop Frame Intermodal Trailer. This drop frame trailer is offered in two body variations — one with smooth riveted sides, and another with horizontal corrugated fluting spanning the length of the trailer body. You would label both designs “dry vans,” because they carry non-perishable cargo.

To even the casual observer, drop-frame dry vans are visually distinct from conventional straight-framed designs due to the deeper body and smaller wheels aft of the trailer’s landing gear. Due to differing size and weight regulations between states in the 1960s and 1970s, a 40-foot trailer was the longest trailer that one could operate lawfully in all states with a highway tractor. At the same time, pressures for greater operating efficiencies from both shippers and transportation companies demanded that trailers be able to transport more with every trip. In response, trailer manufacturers developed the “drop-frame” design to maximize cubic carrying capacity within the mandated 40-foot-long “footprint.” With smaller-diameter highway wheels allowing for a lower floor, 40-foot drop frame trailers provide an average of 14 percent more room than a straight-floor trailer of equivalent length.

Railroads, trucking companies, and moving companies quickly adopted the new drop-frame designs for hauling low-density freight, such as furniture, appliances, certain non-perishable foodstuffs, and other light commodities. Nearly every major trailer manufacturer produced drop-frame trailers for intermodal service, including Fruehauf, Dorsey, Black Diamond, Budd, Kentucky, Theurer, and many others. Drop-frame trailer designs were common sights in railroad intermodal service from the late 1960s through the mid-1980s. At the height of their popularity, I would venture to say that nearly every TOFC (trailer-on-flatcar) train in the 1970s had at least a few drop-frame trailers riding along.

Whether drop-frame or straight-frame, both the fluted-side and smooth-sided vans share nearly identical construction above the trailer floor. In the trucking industry, both styles are simply known as “sheet and post dry vans.” A sheet and post dry van of the 1960s and 1970s was comprised of a steel or aluminum skin on the outside. The outer skin is sandwiched to plywood walls separated by metal posts. Each metal post is punctuated with tie-down slots used to anchor lading. All this is riveted together to form the side walls of the trailer. The roof of the van is formed from metal cross members supporting an outer skin made of thin sheet metal.

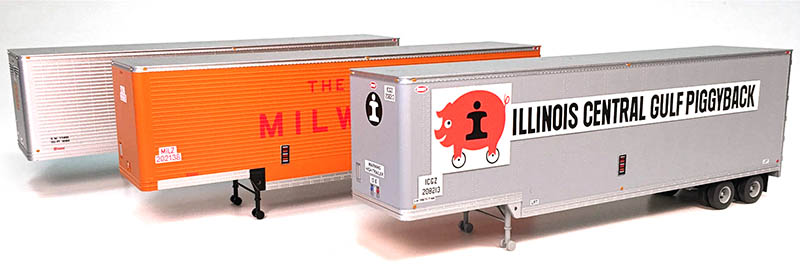

For the inaugural release in HO scale, Trainworx has released drop-frame vans in six paint schemes. Trainworx offers the smooth-sided version of its drop-frame dry van in Norfolk & Western, Illinois Central Gulf, and Family Lines paint. The fluted-side version of the trailer is offered in The Milwaukee Road, Union Pacific, and Santa Fe schemes. Each paint scheme is offered in three different road numbers. Undecorated versions of each body style are also available.

For the inaugural release in HO scale, Trainworx has released drop-frame vans in six paint schemes. Trainworx offers the smooth-sided version of its drop-frame dry van in Norfolk & Western, Illinois Central Gulf, and Family Lines paint. The fluted-side version of the trailer is offered in The Milwaukee Road, Union Pacific, and Santa Fe schemes. Each paint scheme is offered in three different road numbers. Undecorated versions of each body style are also available.

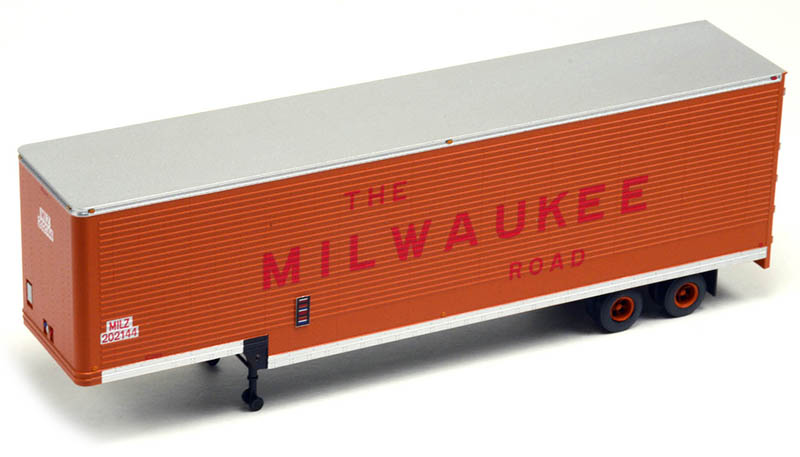

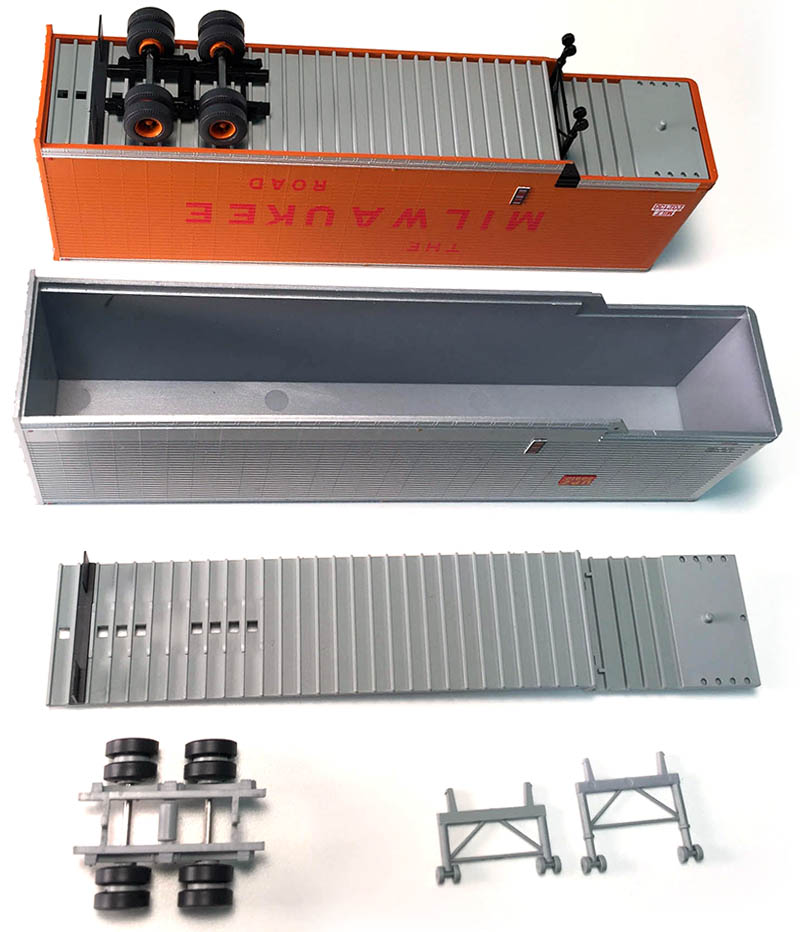

Regardless of body style, each trailer is comprised of a one-piece styrene body shell, a single-piece floor with separately applied landing gear, trailer bogies, and mud flap assemblies. Depending upon the paint scheme, separate placards are applied to the model for lettering, ACI labels, and reporting marks. All parts are finely molded in styrene. Each placard is made of etched brass, pad-printed, and glued to the trailer. Metal axles are provided for the trailer wheels, which are free-rolling. Of the 12 examples I examined, all were assembled perfectly without error. All lettering and placards are neatly applied and in proper alignment from all angles.

Each trailer includes a number of details configurable by the customer. Straight out of the box, every trailer comes with landing gear installed in an extended position ready to be parked most anywhere on your layout. Back in the box under the clam-shell packaging, you will find an alternate set of shorter landing gear. You can use the shorter landing gear assembly to simulate a trailer with its gear retracted upward. This is perfect for positioning your drop-frame van on an intermodal flatcar or behind a semi-tractor. Swapping out the landing gear is easy. Pull out each side of the landing gear a little bit at a time with gentle finger pressure until the one-piece landing gear assembly separates from the floor of the trailer. Simply push in the mounting pegs for the desired landing gear until the assembly seats gently against the trailer floor.

The other major configurable features on the model are the positionable trailer bogie and mud flap assemblies on the model. Both the bogie and mud flap assemblies have four possible positions, and each can be positioned independently of one another. To change the position of the bogie or the mud flaps, gently tug on either assembly until it separates from the floor of the trailer. Find a new pair of pre-drilled holes in the floor for the trailer bogie or mud flap assembly and simply press each assembly into their new positions. No glue required nor needed. I found that the bogies and mud flap assemblies fit snugly into each adjustment position with just easy finger pressure. Perfect!

The underframe kingpin diameter measures out at 0.057-inches, which was a hair larger than the hole on the ACF Model 5 trailer hitches on my Athearn Genesis F89F flatcar. To fix that, simply use a 1/8-inch drill bit to ream out the hole just a tad. I did not encounter any issues with mounting the trailer on the trailer hitches of 89-foot TOFC flatcars from other manufacturers, including those from Atlas, BLMA, and Walthers. Each trailer weighs approximately 1.25 ounces. If desired, additional weight can be easily added to each trailer. The floor is secured to the shell by friction fit and is easily removed from the body shell.

Both body styles (fluted and smooth-sided) share a common floor, landing gear, and wheels. Examining the details on each body shell, I found that the nose, roof, and end doors are identical between both body styles. The fluted trailer matches prototype photos for a corrugated- side drop-frame dry van manufactured by Brown Trailers Inc. from all angles that I have observed. The side walls of the smooth-sided dry van are a perfect match for a drop-frame dry van built by Fruehauf.

Prototype photos of drop-frame trailers are difficult to come by, but I was able to come across direct matches to the models for the Milwaukee and Union Pacific schemes.

The front nose wall of both body styles has a recessed document box on the right side, with trailer air and electrical connections recessed to either side of the center line of the trailer. The corner posts of the nose are curved in a manner typical of most drop-frame trailers manufactured by Brown and Fruehauf. The rear doors feature two door rods and five hinges per door — an arrangement consistent for trailers serving in railroad intermodal service.

All decorations on each trailer are pad-printed onto the trailer body and onto the separately applied etched brass signage panels as mentioned before. All pad printing was rendered sharply. The paint separations between the main body color and the roof and base rails on each trailer were crisply rendered. Taillights and marker lamps also are pre-painted nicely on the models. The pre-printed lettering on the mud flaps varies depending on the paint scheme and manufacturer depicted on each trailer — a welcome touch. All schemes have underframes, landing gear, and wheel centers painted in a light gray with two exceptions. The Milwaukee Road trailer sports orange wheels and black landing gear, and the Great Northern version has gray wheels with red landing gear. The only thing remaining to add to these trailers are license plates, which often vary in mounting location. License plates can be easily applied using an aftermarket decal set such as Microscale set MC-4168 or from other sources.

With their first HO-scale release, Trainworx has answered the decades-long wishes of many HO-scale modelers seeking a proper mix of trailers in their piggyback trains with not only one style, but two different drop-frame 40-foot intermodal vans in both smooth-sided and fluted-side versions.

This pair of drop-frame vans from Trainworx fills a huge void for modelers of the late 1960s through the mid-1980s when these distinctive trailers were a common sight nationwide in piggyback service. We welcome Trainworx to the world of HO scale. We look forward to further releases of these HO-scale trailers in additional schemes and road numbers in the future.

40-Foot Drop-Frame Intermodal Trailer

MSRP $24.95

Roadnames: Great Northern, Illinois Central Gulf, Union Pacific, Family Lines (SCL/L&N), Santa Fe, Norfolk & Western, Milwaukee Road

Trainworx

PO Box 127

Delta CO 81416

970-874-9747