Review by Harry K. Wong/photos by the author

Review by Harry K. Wong/photos by the author

At its peak, Southern Pacific was an 13,800-mile system serving the American Southwest stretching from Los Angeles to Portland, Ore., St. Louis, Mo., and New Orleans, La. In an effort to improve braking performance on long trains in mountainous territory, SP created a fleet of seven air repeater cars between 1975 and 1977 from existing Pacific Car & Foundry insulated plug door boxcars built in 1959. Now equipped with a diesel-powered air compressor and additional air reservoirs, the goal of these air repeater cars was to provide faster train line charging time, reduce or eliminate brake pipe pressure gradient, provide more uniform braking forces, and deliver faster brake application and release times when positioned midtrain. These cars were based out of yards in Eugene, Ore., Roseville, Calif., and Sparks, Nev. In later years, some of these cars were also used to provide auxiliary air at SP’s commute train terminals at San Jose and San Francisco.

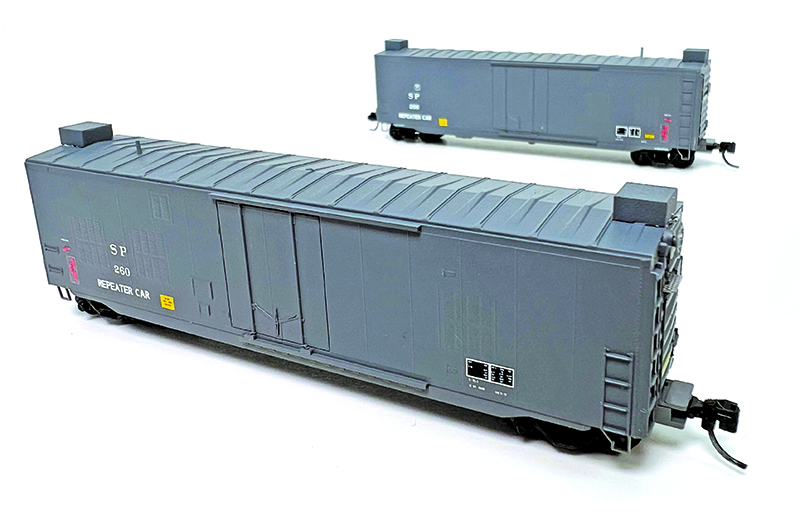

One of the latest releases from Micro-Trains Line is a pair of SP Air Repeater Cars. This offering is provided as an easy-to-assemble kit which includes two cars with separate 3D-printed rooftop details to be added by the modeler. The kit is available packaged either with jewel cases or in a “foam family nest” (pre-cut foam enclosure) as we received it.

The boxcars come pre-assembled with add on details that can be placed on the roof by the modeler.

Both models are equipped identically with a mixture of different-height ladders molded on at each corner of the car body with no running boards atop the roof and a fishbelly-profile side sill, carryovers from this model’s origins as a standard 50’ boxcar from MTL’s existing lineup. Factory-applied parts include a finely cast plastic brake wheel mounted in the correct high position on the B-end, and an etched metal platform with round perforations under the brake wheel.

Underframe details include a standard AB air brake system with piping and a Hydra-Cushion cylinder as part of the one-piece center sill assembly. The corner stirrup steps on the model are of fine scale proportions and yet have held up to casual handling around our test layout.

Where this model differs from your standard ready-to-run MTL freight car are the details that make this car a close match to Southern Pacific’s air repeater cars. On the body shell, one will find louver arrangements and fuel gauge details that precisely echo those found on their prototypes. They appear to be 3D-printed resin details applied onto the model. In all, they present an exquisite fine-scale appearance which is stunning to see in N scale.

The final details are the ventilation boxes and exhaust pipe to be added by the modeler onto the roof of each car. Full-color illustrated instructions are included to guide the modeler through the simple process of assembly. I snipped the boxes off of the sprue using a fine sprue nipper. To carve off a portion of the roof corrugations, careful, patient work with a sharp hobby knife will be amply rewarded. The roof boxes were attached with a sparing drop of canopy glue.