by Joe Green/photos by the author

by Joe Green/photos by the author

Freelanced prototype railroads, such as my HO scale Chesapeake & Ohio Ryder Gap Subdivision, can benefit from a plausible, well-defined backstory. Creating a story with realistic elements helps us think through what would motivate the building of our imagined railroad, what business opportunities existed, and what operational issues needed to be solved. It gives us guidance through the design and building of our layout to ensure that what we develop feels like the most realistic approach, while still allowing for a level of creative freedom.

Prototype Scenes

The prototype scenes and locations I wanted to model were on three different C&O subdivisions in western Virginia and eastern West Virginia. I went to high school in Covington, Va., and wanted to include the Westvaco paper mill and Hercules chemical plant. Both were large, thriving industries in the mid-1970s.

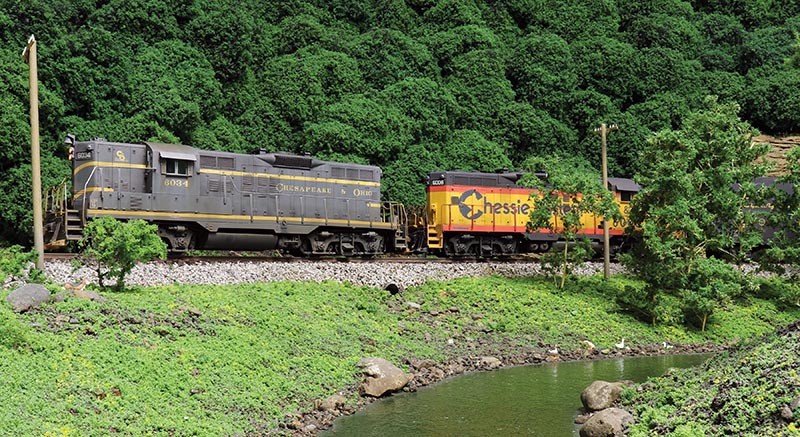

ABOVE: The morning Mill Job passes Back Creek on its way to the paper mill. EMD GP7s and GP9s were ubiquitous on the C&O, and they are on the Ryder Gap Sub as well.

On the other hand, the Cass, W.Va., lumber mill had been shuttered in the early 1960s, and the C&O was in the process of abandoning the Greenbrier Subdivision itself. Two viable industries, Interstate Hardwoods and Howes Leather, were near Durbin, W.Va., just 10 to 15 miles north of Cass. The connecting lumber company branch line into the mountains would begin its second career as Cass Scenic Railroad in 1963.

Finally, I wanted to include the iconic Thurmond, W.Va., scene, with its engine facility and row of brick commercial buildings lining the tracks. But Thurmond was in the heart of coal country, and I wanted my layout to emphasize the C&O’s support of timber-related industries.

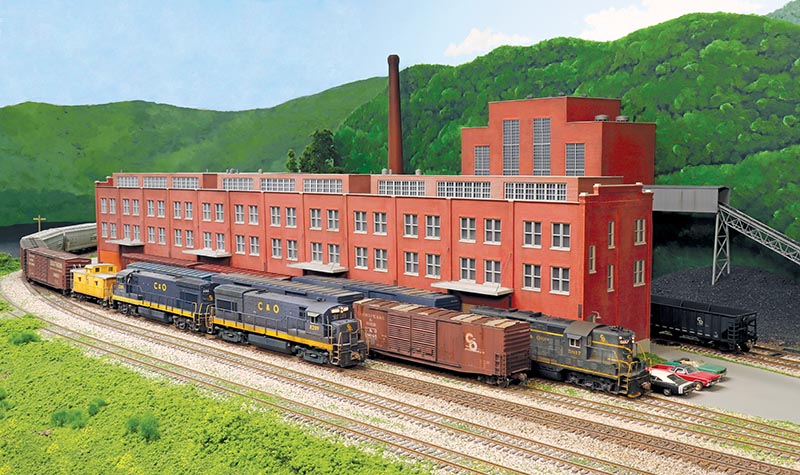

ABOVE: Train 146E rounds the curve by the paper warehouse. Back Creek Paper is the largest customer on the Ryder Gap Sub, shipping 250 tons of paper per day. The warehouse is kitbashed, while the powerhouse behind is scratchbuilt.

I based the Ryder Gap Subdivision on a route that the C&O Engineering Department recommended for the Greenbrier Subdivision, but that was rejected by the board in favor of a different proposal. Let’s get an overview of the subdivision by reading a report written by its superintendent at the request of upper management. It is the spring of 1974, the railroad industry is in turmoil following Penn Central’s failure just four years ago, and C&O is now under the banner of the combined Chessie System. The Ryder Gap Sub’s future is in question…

Per your request, please find attached the review of the Ryder Gap Subdivision for the upcoming regional operations planning cycle. It includes an overview of the physical infrastructure, key customers, current operations, and strategic recommendations. The Accounting Department will cover financials in a separate document.

Physical Infrastructure

The subdivision stretches 86 miles from Covington, Virginia, to Durbin, W.Va. It was originally built to access timber in the Greenbrier River Valley, particularly connecting Westvaco’s lumber mill in Cass to its pulp and paper mill in Covington.

The single-track mainline and physical plant mostly date from the early 1900s. Traffic moves under timetable and train order without signals.

The eastern 28 miles to Mountain Grove, Va., have a 0.5% grade and no tunnels. The Covington pulp mill is reached within the first mile; no other customers exist east of Mountain Grove. This segment is well maintained due to significant traffic.

ABOVE: The Farm Job prepares to switch Highland Chemical to the left of the photo. Westbound cars are in the adjacent siding. The farm scene helps to reinforce the rural, mountain setting surrounding the industrial scenes.

Mountain Grove is the operational hub with two yards. Thomas Yard handles classification with nine tracks and capacity for 175+ cars. The two setout tracks are by the paper mill. May Yard formerly served steam engines but now handles light freight car repairs after removal of excess track. We recently abandoned the small yard at Natural Well near Hot Springs Branch Junction. Classification formerly done there is now consolidated at Mountain Grove.

The next 18 miles to Marlinton, W.Va., cross the Alleghenies through Ryder Gap. Westbounds face a 1.7% ruling grade. The last 40 miles to Durbin follow the Greenbrier River on a gentler grade. Durbin has a wye and interchange with the Western Maryland. Maintenance has been deferred on this section — including five tunnels — since the Cass mill and Marlinton tannery closed.

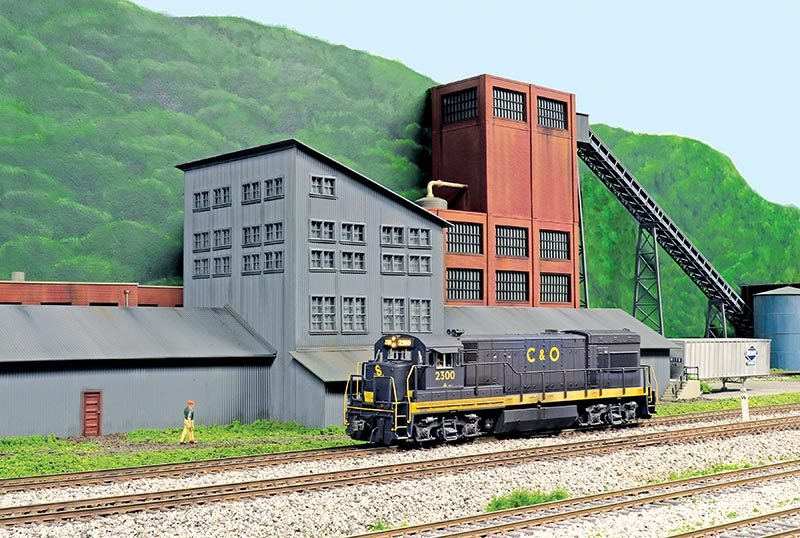

ABOVE: he morning Mill Job crew has been discussing plans with the traffic manager. The digester, the heart of the pulping process, looms behind the U23B. These structures and track plan are inspired by the Westvaco mill in Covington, Va.

There is also a 35-mile branch from Mountain Grove to Monterey, Va., via Mill Gap. The line is lightly maintained; the two main customers are in Mill Gap. Funding has been approved to reroute part of the line due to a new dam on Back Creek for the Bath County Pumped Storage Station.

Customer Base

Back Creek Paper in Mountain Grove is by far our largest customer, with approximately 125 inbound and 65 outbound shipments weekly. The mill produces high-quality writing paper. We switch it twice daily, guided by lists from their traffic manager...